Weld Shaver

Weld Automation

The weld shaver carriage uses force compliance to allow the weld shaver head to maintain contact over contoured surfaces and ensures a consistent and precision weld removal. Force compliance technology combined with DC Servo Spindles increases:

Quality

Consistency

Cutter Insert Life

Operator Safety

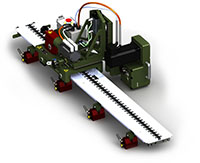

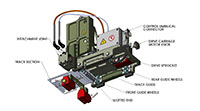

The weld shaver removes up to 90% of the weld height at a rate of up to 3 ft/min (61 cm/min) and can remove welds of 0.375 - 3 Inches (0.9525 - 7.62 cm). The weld shaver system is an automated solution for the rapid removal of weld beads above a panel surface. The Weld Shaver is moved along a track by the Drive Carriage with the user managing everything remotely from the Control Console. The TWS91 System is comprised of five major components; the Track (either Flex or High-Flex), the Drive Carriage, the Weld Shaver, the Control Umbilical, and the Control Console.

Quality

Consistency

Cutter Insert Life

Operator Safety

The weld shaver removes up to 90% of the weld height at a rate of up to 3 ft/min (61 cm/min) and can remove welds of 0.375 - 3 Inches (0.9525 - 7.62 cm). The weld shaver system is an automated solution for the rapid removal of weld beads above a panel surface. The Weld Shaver is moved along a track by the Drive Carriage with the user managing everything remotely from the Control Console. The TWS91 System is comprised of five major components; the Track (either Flex or High-Flex), the Drive Carriage, the Weld Shaver, the Control Umbilical, and the Control Console.

Unit of Measure